Canon launched its ceramic 3D printing service in China in 2022, which is an important step into the field of additive manufacturing. Canon developed two types of composite ceramic powder materials, which is mainly composed by alumina and silica. By using SLM selective laser melting technology (SLM technology), Canon produces complex shapes parts with ceramic powder by 3D printing.

As is well known, ceramics has advantages such as high temperature resistance, friction resistance, corrosion resistance, insulation, etc., Compared to traditional metal and plastic material, ceramic 3D printing is much more difficult. Canon has broken through this technological limitation and expanded the application of ceramics in precision manufacturing field, In the future, ceramic 3D printing parts may be used in many industries such as aircraft engines, lithography machines, electric vehicles, etc.

Ceramic material + SLM technology

With independently developed ceramic materials for 3D printing, and SLM technology, Canon starts to provide ceramic 3D printing services, which has advantages as below:

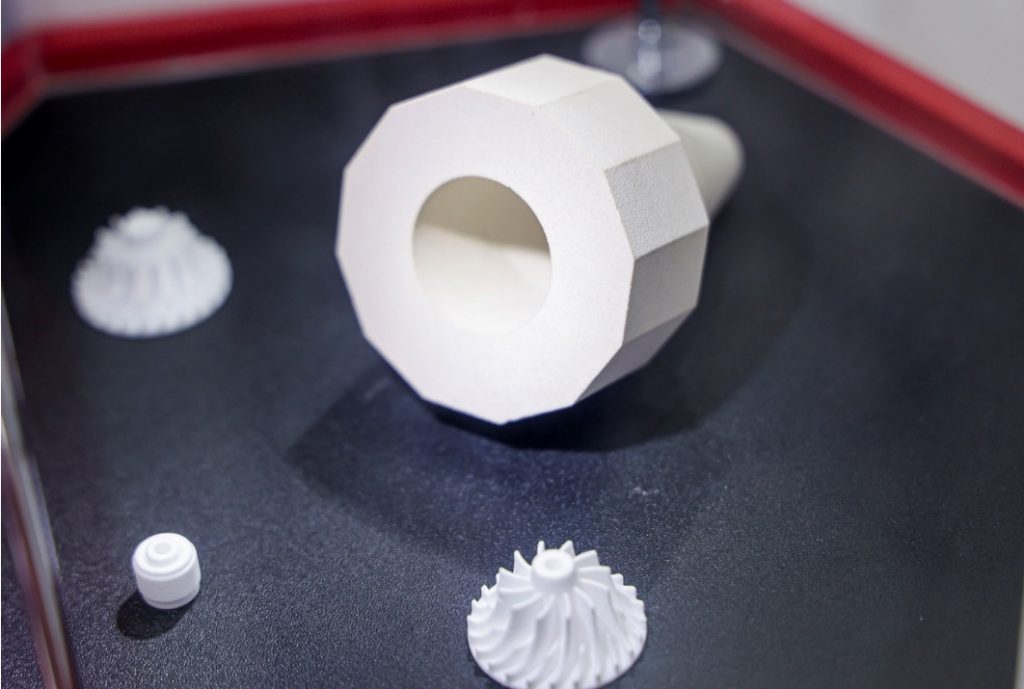

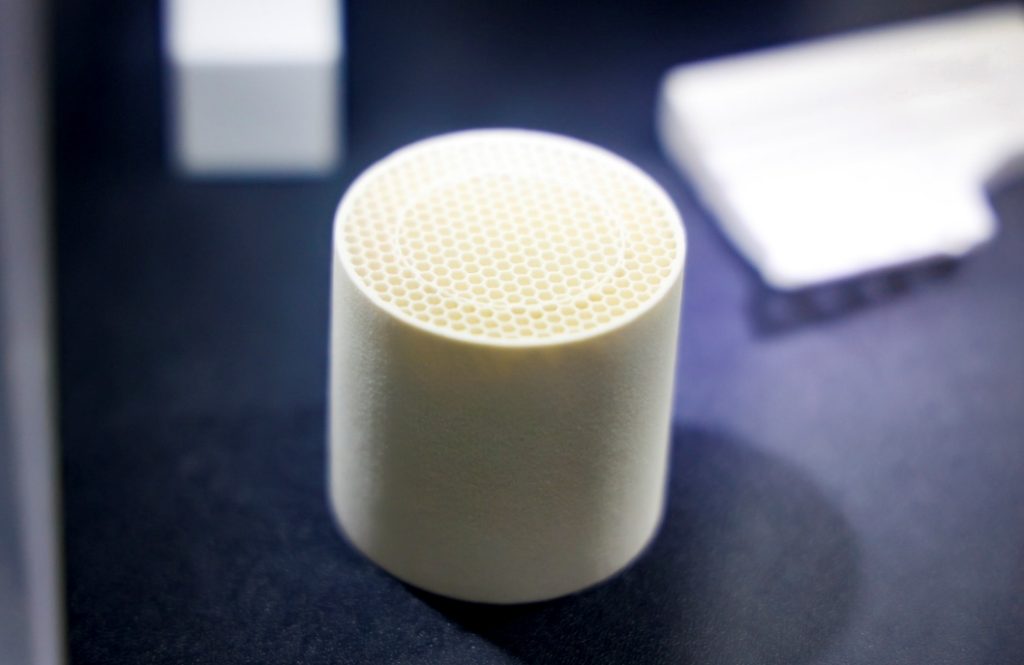

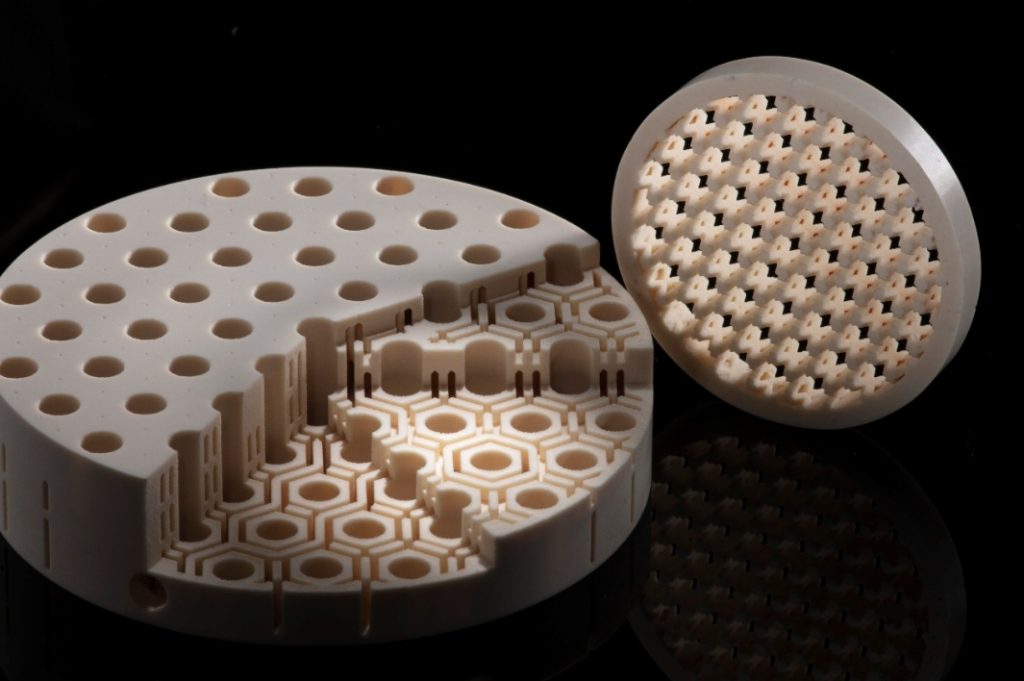

- Possible to produce complex shaped (such as with multi flows inside) parts. achieves φ0.5mm holes, thickness 0.4mm ~ 25mm, and max. size 200mm * 200mm * 200 mm;

- Canon’s ceramic materials and SLM printing process do not include resin adhesives, which means no need for degreasing process, so that parts quality is much more improved;

- The shrinkage ratio after sintering is less than 2%, and sintering time only takes 1-3 days.

Due to the absence of resin binders in ceramic materials and shaping process, Canon can prevent the common problems caused by resin, such as severe shrinkage after sintering, difficult for degreasing, easily cracking…etc., and improved the accuracy and stability of 3D ceramic shaping.

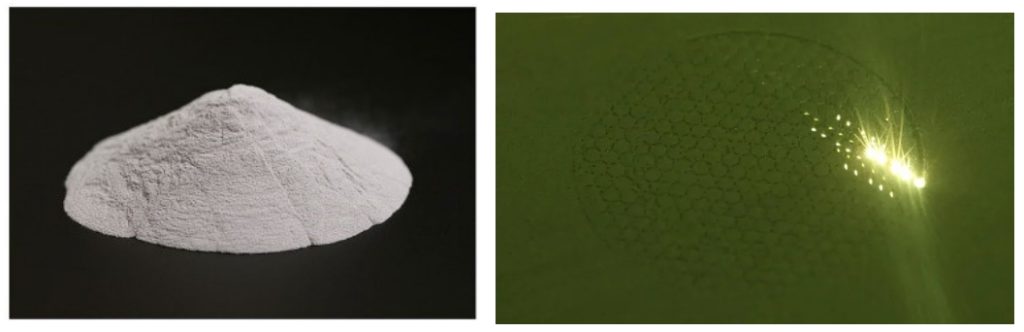

SLM technology is mainly used in metal 3D printing , and is rarely applied to ceramic materials. This is because the melting point of alumina ceramic powder is above 2000 ℃, which is too high to be melt by laser. by adding rare metal oxides component into alumina powder, which helps to absorb infrared laser heat, Canon successfully reduced the melting point of ceramic powder, and makes it possible to shape ceramics by using SLM technology.

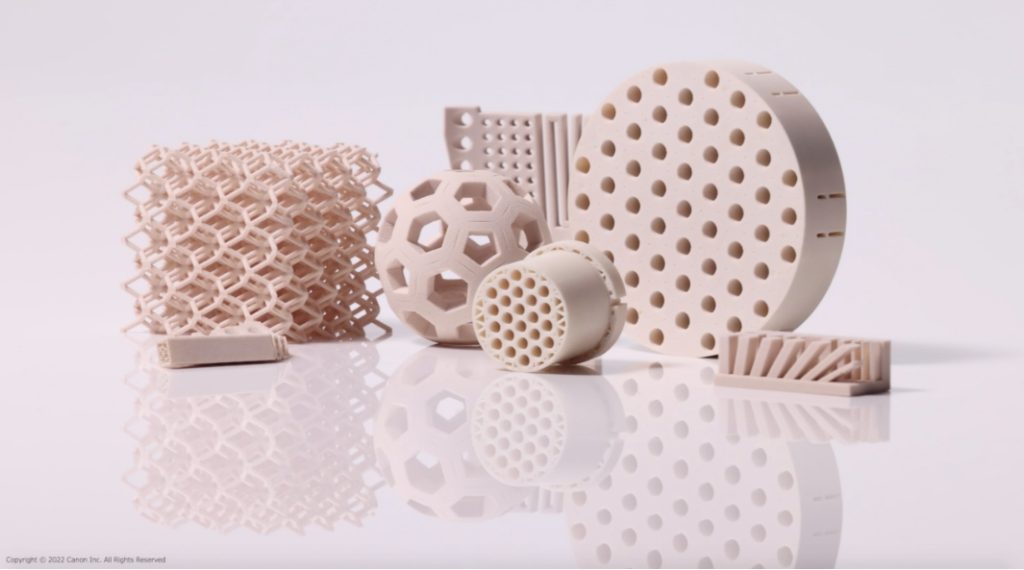

Please take a look at Canon ceramic 3D printing samples.

With future development of 3D printing technology, it is expected that precise ceramic parts to be more applied in multiple industrial fields such as aerospace, semiconductors, medical equipment, automotive manufacturing, precision instruments, scientific research and development…etc.

You can contact Canon for more information.

Tel:010-85139545

E-mail: 3dprintservice@canon.com.cn

Homepage: https://www.canon.com.cn/product/ceramics3d/

Remark: The data cited in this article is sourced from Canon Japan’s statistics.